News

Note that the releases are accurate at the time of publication but may be subject to change without notice. This page shows only the most recent items. For the full archive of press releases please click "Search by category or year."

Mitsubishi Electric Develops World’s First Technology to Use Microbubbles to Generate Millimeter-scale Flow in Channel

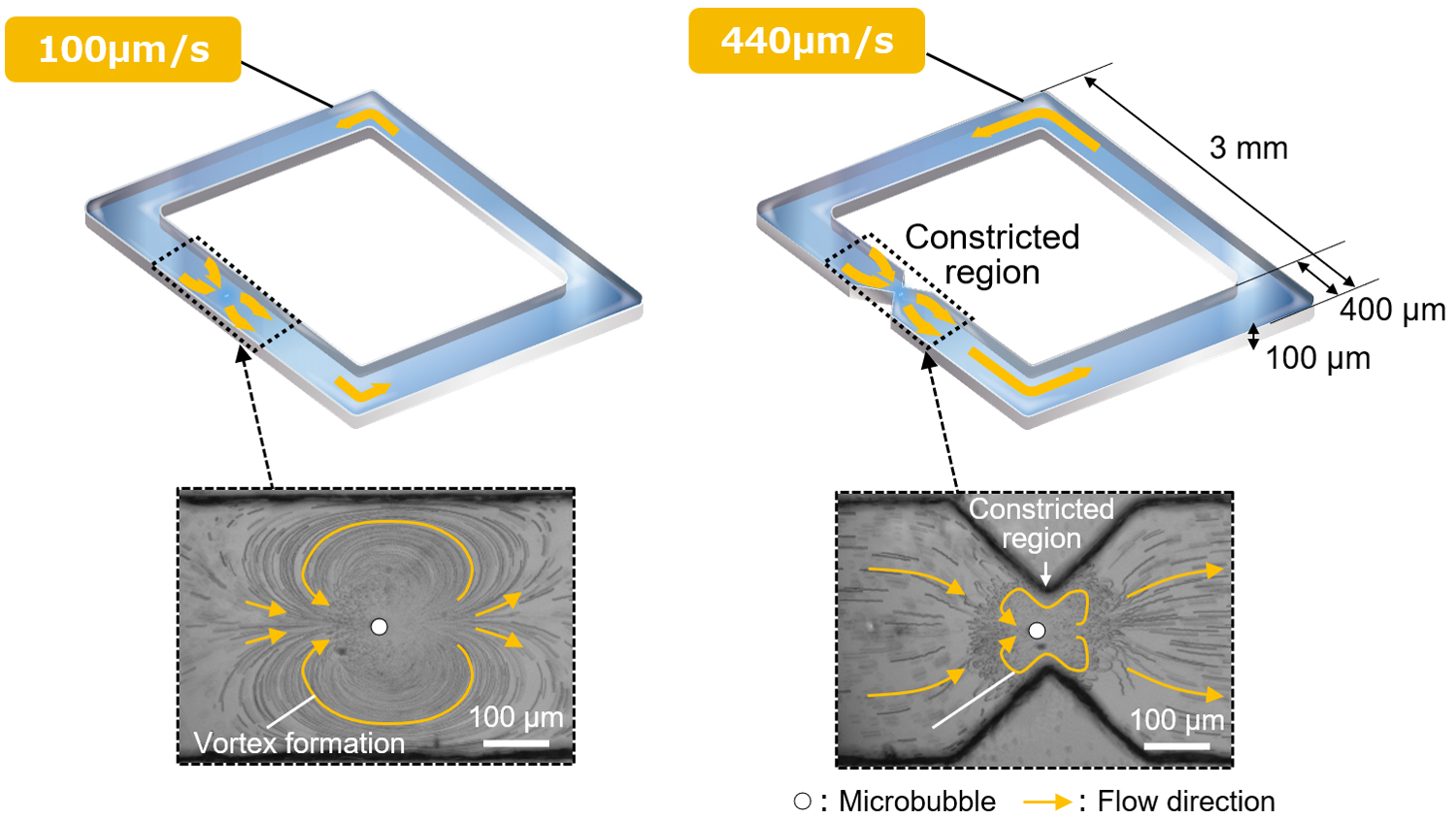

Flow generation in a microchannel by microbubbles

TOKYO, December 4, 2025 - Mitsubishi Electric Corporation (TOKYO: 6503) announced today that it has developed the world’s first1 technology to generate millimeter-scale flow within a channel by using microbubbles with a diameter of 10μm as the driving source. Developed through joint research with Suzuki & Namura Laboratory at Faculty of Engineering and Graduate School of Engineering, Kyoto University, this technology is expected to reduce power-consuming external pumps for water cooling in electronic equipment, thereby contributing to carbon neutrality.

Thermal management is becoming increasingly important for electronic devices due to their high output and the growing computation load of AI servers as generative AI rapidly spreads. Electronic devices that generate large amounts of heat require water cooling systems,2 and demand is expanding for cooling systems that circulate liquid through microchannels to achieve greater efficiency than conventional water cooling systems. To further improve the efficiency of microchannel cooling, efforts are being made to reduce the microchannel width to 100μm or less. However, a powerful external pump is required to circulate liquid in microchannels, so the increasing power consumption of these systems has become an issue.

Kyoto University developed a technology that uses microbubbles generated by local heating and Marangoni forces3 arising from temperature differences at vapor-liquid interfaces and self-oscillation to induce flow. Mitsubishi Electric researched methods to apply this technology to a microchannel and succeeded in generating a world-first flow speed of 100μm/s in a 3mm x 3mm square channel with a cross section of 100µm x 400µm, all without using external pumps. Later, the flow speed was improved to 440μm/s by optimizing the bubble layout and flow-path geometry. Going forward, Mitsubishi Electric aims to enhance the energy saving and high performance of next-generation cooling systems to contribute to carbon neutrality.

This research result was selected for publication in Applied Physics Letters,4 an international journal on applied physics published by the American Physical Society.

- 1

According to Mitsubishi Electric research as of December 4, 2025.

- 2

Other methods such as air cooling and immersion are used depending on the application, heating value and installation environment of the electronic equipment.

- 3

Fluid force driving mass transfer at liquid interface.

- 4

Inquiry

-

Customer Inquiries

Advanced Technology R&D Center

Mitsubishi Electric CorporationFax: +81-6-6497-7285

https://www.MitsubishiElectric.com/ssl/contact/company/rd/form.html

Search by category or year of publication

There are no articles for the condition you specified.